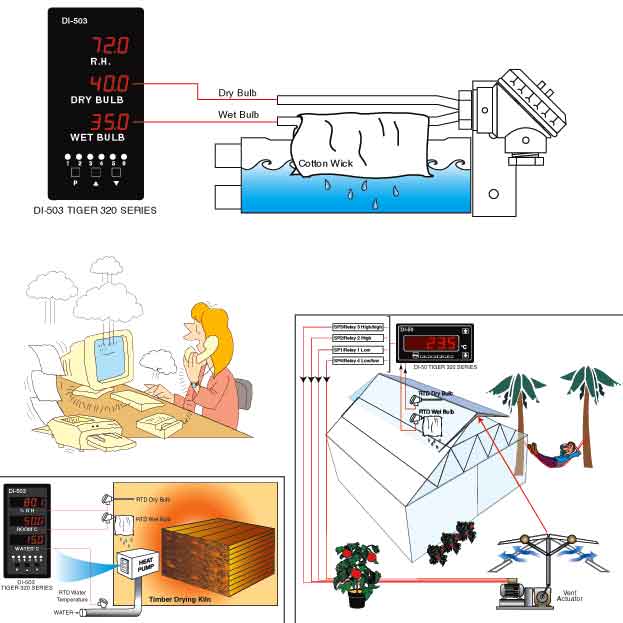

Application Examples 55_Wet and Dry Bulb Humidity Measurement and Control

Wet and dry bulb humidity measurement, using two temperature sensor probes, is perhaps the most reliable method of accurately calculating humidity for low temperature applications in industry today. Both sensors are mounted close together, with one designated the dry bulb sensor and the other the wet bulb sensor. The wet bulb is kept wet using a moistened cotton wick.

The wet bulb is cooled relative to the dry bulb by heat loss due to moisture evaporation from the wet bulb wick. The rate of evaporation is dependent on the ambient temperature and humidity.

From a polynomial formula entered into the controller, relative humidity (RH) is calculated from the dry and wet bulb temperatures.

A Tiger 320 Series controller, with a dual RTD or thermocouple input module and our relative humidity macro installed, allows you to directly display RH and temperature. This data can be used to control the temperature and humidity applications in horticulture, livestock, food processing, environmental, timber drying, and many other industries.

- Download PDF » (402.7 KB)